Every single electronic device you use today has a printed circuit board, or PCB, that operates the device. To make PCB units, you can hire a PCB assembly company outside of your company that offers high-quality PCB assembly services in the USA.

What is PCB assembly service?

The PCB assembly services are part of the electronics manufacturing process. It involves mounting electrical components on printed circuit boards using advanced technology. This process is also known as printed wiring assembly, circuit card assembly, and electronics assembly.

PCB assembly services that are accurate and work well are essential because they are key to the growth of the electronic device industry. It also comes with other benefits, such as saving manufacturers from spending money on labor costs.

How Does the PCB Assembly Process Work?

A PCB assembly company follows these processes to provide their clients with efficient PCB services, including:

Solder Paste

The first step in the traditional PCB assembly process is applying solder paste to the board. The assemblers place the mask, a thin, stainless-steel stencil, over the PCB as it allows them to apply solder paste to specific parts of the board.

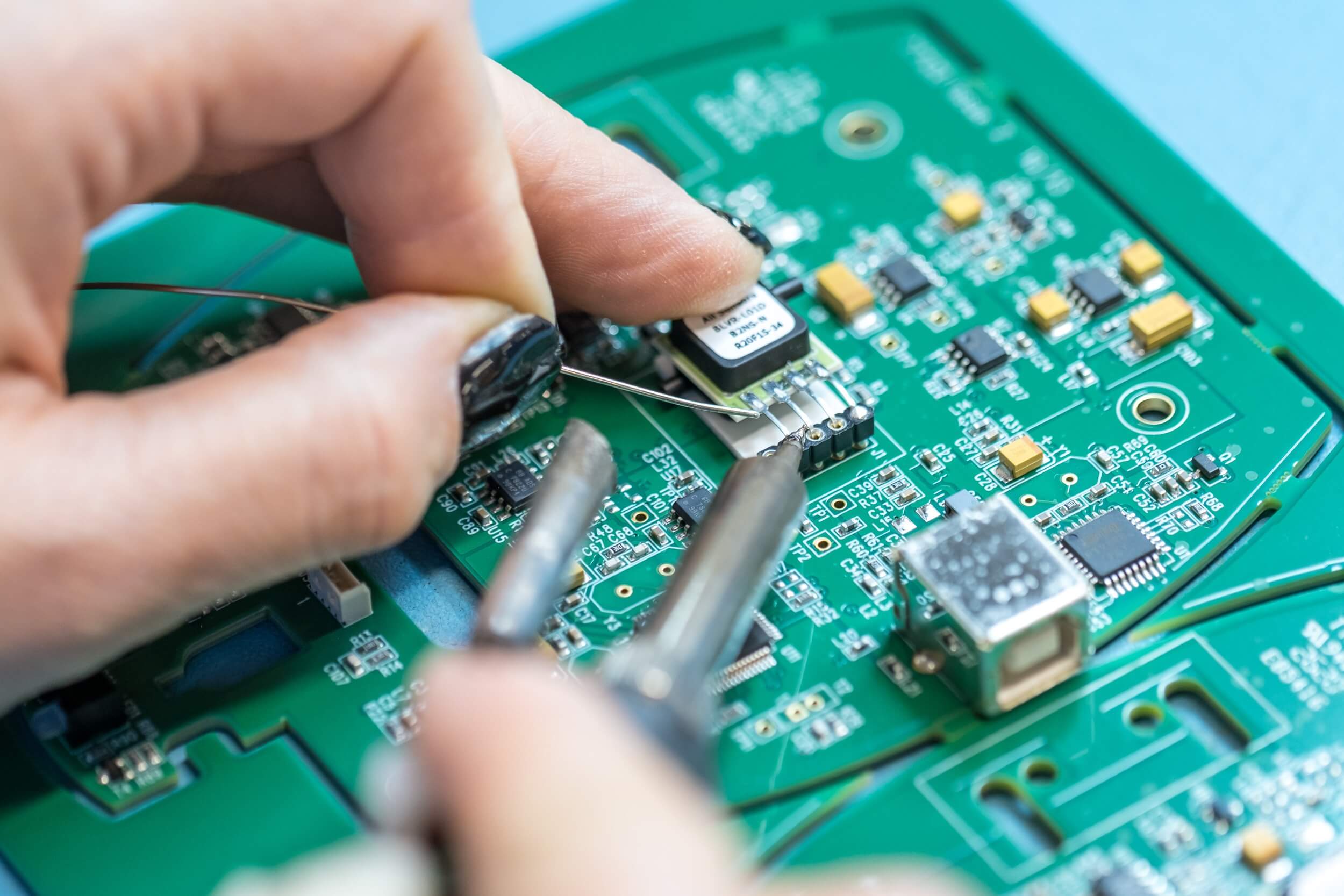

Placing the Component

The next step of the process is to place the components on the board. The assembler may do it manually (THT assembly) or use machinery (SMT assembly) to set the component.

Reflow

In this PCB assembly process, the assembler first melts the solder and resolidifies it. In this process, the board and its parts go through an oven, which heats the solder and makes it easier to work. After the assembler ensures connections are formed, they move it into a cooler to solidify the solder.

Inspection

The assembler visually inspects the board, soldering, and components to ensure placement accuracy.

Insertion

In this step, the assembler performs through-hole insertion after the reflow and inspection. Assemble may also use wave soldering, a process that liquefies the solder of the entire board and moves it through a cooler to solidify the solder.

Final Testing and Cleaning

In the final step of PCB assembly, the assembler inspects the shoulder points, board, and components. They also clean the board to ensure the excess solder is removed from it.

Conclusion

PCBs are valuable in various industries, from computers to cars to control systems. If you are looking for excellent PCB assembly services in Seattle, you can contact Aaloktronix. We offer high-quality PCB assembly services using open-source technology at affordable prices.