Insufficient wetting, a common issue in PCB assembly, refers to the inadequate spreading and adherence of solder to the surface of the components and PCB pads during the soldering process.

Understanding the root causes, potential implications, and effective solutions for enhancing solder wetting is crucial for ensuring the reliability and functionality of printed circuit boards.

In this detailed exploration, we will delve into the underlying causes of insufficient wetting, analyze its potential impacts on PCBs, and provide practical strategies to improve solder wetting and mitigate this prevalent issue in PCB assembly.

Causes of Insufficient Wetting:

Insufficient wetting can result from various factors, including surface contamination, oxidation, or improper soldering conditions. Surface contamination, such as the presence of oils, dirt, or residues, can hinder the wetting ability of the solder, leading to poor adhesion and incomplete solder joints.

Oxidation of the solder surface or the component leads can also impede solder wetting, creating barriers that prevent the solder from forming a robust metallurgical bond with the surfaces.

In addition, inappropriate soldering temperatures, inadequate flux application, or the use of low-quality solder materials can contribute to insufficient wetting, resulting in weak and unreliable solder connections.

Impacts of Insufficient Wetting on PCBs:

Insufficient wetting can have detrimental effects on the performance and longevity of PCBs, particularly in terms of electrical conductivity and mechanical stability. Incomplete solder joints due to insufficient wetting can lead to increased electrical resistance, voltage fluctuations, and potential signal integrity issues, compromising the overall functionality of the PCB.

Furthermore, weak solder connections resulting from insufficient wetting can jeopardize the mechanical stability of the components, leading to poor shock and vibration resistance, increased susceptibility to mechanical stress, and potential mechanical failures during operation.

Identifying Insufficient Wetting:

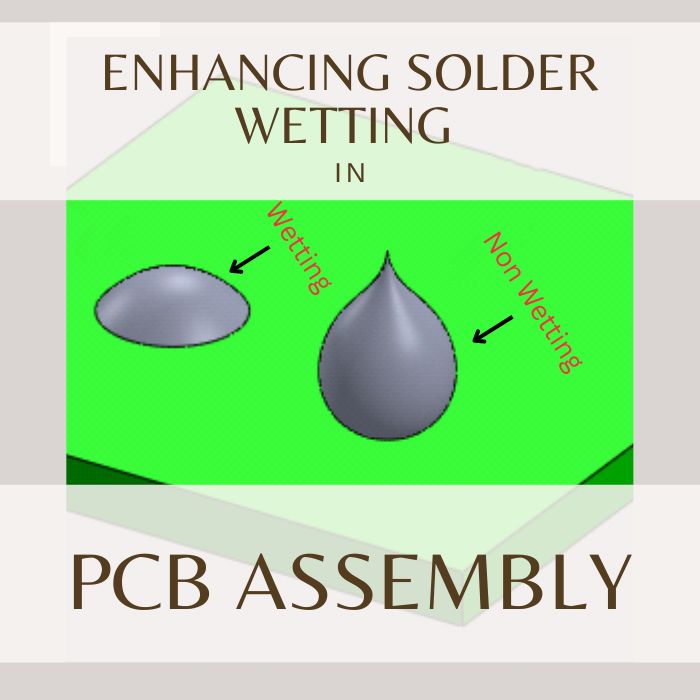

Identifying insufficient wetting requires a comprehensive visual inspection of the soldered joints, focusing on the uniformity and completeness of the solder coverage on the component leads and the PCB pads.

Solder joints with insufficient wetting typically appear as irregular, patchy, or grainy structures, with uneven surface textures and visibly poor adhesion to the surfaces.

Utilizing magnification tools, such as magnifying lenses or digital microscopes, can aid in the accurate identification and assessment of insufficient wetting during the inspection process.

Remedies and Prevention Strategies:

To enhance solder wetting and prevent the occurrence of insufficient wetting, implementing targeted remedies and preventive strategies is essential during the PCB assembly process.

Ensuring the cleanliness of the soldering surfaces through thorough cleaning and degreasing processes can promote optimal solder wetting and improve the adhesion of the solder to the component leads and the PCB pads.

Employing high-quality flux, compatible with the solder and surface materials, can facilitate the removal of surface oxides and contaminants, promoting superior wetting and the formation of reliable solder joints.

Adjusting the soldering temperature and duration to the specifications recommended by the solder and component manufacturers can aid in achieving the ideal balance between sufficient heat transfer and controlled solder flow, ensuring complete wetting and the formation of robust solder connections.

Implementing automated soldering equipment with precise temperature control and programmable soldering profiles can further enhance the consistency and reliability of solder wetting, particularly for high-volume PCB assembly processes or complex soldering applications.

Conducting regular solderability tests and quality control inspections can also aid in the early detection of potential wetting issues and the prompt implementation of corrective measures, ensuring the production of high-quality, defect-free PCB assemblies and electronic products.

Conclusion:

In conclusion, comprehensively understanding the intricacies of solder wetting in PCB assembly is critical for ensuring the reliability and performance of electronic devices and systems. By addressing the root causes, assessing the implications, and adopting effective remedies and prevention strategies, manufacturers and electronics enthusiasts can significantly enhance the soldering quality and integrity of their PCB assemblies, contributing to the development of robust, high-functioning electronic applications and technologies.