Choosing the right PCB substrate material is one of the most important decisions in the design and manufacturing process.

The substrate is the foundation of your printed circuit board, directly affecting its performance, durability, cost, and reliability.

But with so many options—FR4, polyimide, Rogers, ceramics, and more—how do you decide which one is best for your project?

In this guide, we’ll break down the most common PCB substrate materials, their pros and cons, and how to select the right one based on your application.

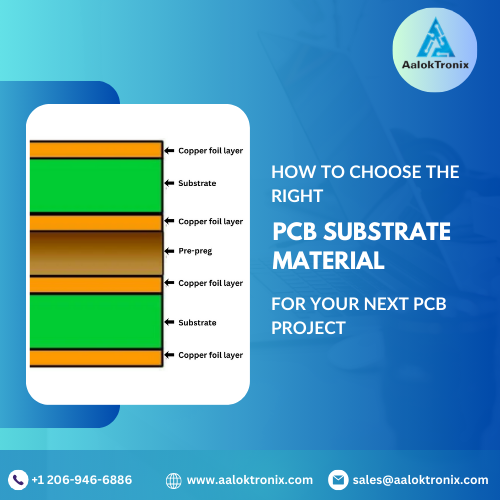

What is a PCB Substrate Material?

A PCB substrate is the base material that provides mechanical support and electrical insulation for the copper traces and components. It determines key properties such as:

- Thermal stability – how well it performs under heat.

- Dielectric constant (Dk) – which affects signal speed.

- Moisture resistance – important in harsh or humid environments.

- Cost and manufacturability – impacts your project’s budget and scalability.

Common Types of PCB Substrate Materials

1. FR4 (Fiberglass Epoxy) – The Industry Standard

- Best for: General electronics, consumer devices, and cost-sensitive projects.

- Pros: Affordable, good electrical insulation, widely available.

- Cons: Limited high-frequency performance, average heat resistance.

2. Polyimide – High-Performance Flexibility

- Best for: Flexible PCBs, aerospace, automotive, and high-temperature environments.

- Pros: Excellent thermal stability, flexible, resistant to chemicals.

- Cons: Higher cost compared to FR4.

3. Rogers Laminates – High-Frequency Applications

- Best for: RF/microwave circuits, 5G devices, communication equipment.

- Pros: Low dielectric loss, stable performance at high frequencies.

- Cons: Expensive, requires careful handling during manufacturing.

4. Ceramic Substrates – Extreme Reliability

- Best for: Power electronics, medical devices, aerospace systems.

- Pros: Outstanding thermal conductivity, excellent durability.

- Cons: Very costly and harder to process.

How to Choose the Right Substrate for Your Project?

When selecting a PCB substrate, consider these key factors:

Operating Environment:

- Will the board be exposed to high temperatures, moisture, or vibration?

- Example: Automotive ECUs require polyimide or ceramic for stability.

Signal Speed & Frequency:

- High-speed digital or RF circuits need Rogers for low signal loss.

- Consumer gadgets can usually rely on FR4.

Budget & Volume

- For mass production of cost-sensitive devices, FR4 is the go-to.

- For specialized, low-volume projects, premium materials may be justified.

Mechanical Requirements

- Flexible devices (like wearables) need polyimide.

- Rigid devices (like industrial controllers) work well with FR4.

FAQs About PCB Substrate Selection

Q: Can I use FR4 for high-frequency designs?

A: Yes, but it’s not ideal for frequencies above a few GHz. Rogers or other high-frequency laminates are better.

Q: What’s the most cost-effective substrate for prototypes?

A: FR4 is the most affordable and widely used, making it ideal for prototyping unless your design has special requirements.

Q: Do different substrates affect PCB lifespan?

A: Absolutely. Selecting the wrong substrate can result in overheating, signal loss, or premature board failure.

Final Thoughts

The PCB substrate material you choose can make or break your project’s performance and cost-efficiency. Whether you need a budget-friendly FR4 for consumer electronics or high-end Rogers for advanced communication systems, selecting the right material ensures long-term reliability.

At Aaloktronix, we help clients across industries design and manufacture PCBs with the right substrate for their unique needs. From prototype to mass production, our expert engineers guide you every step of the way.

???? Looking for expert PCB manufacturing support? Contact us today and let’s build the right foundation for your next project.