Tombstoning, a common phenomenon in PCB soldering, refers to the vertical lifting of a surface mount component during the reflow process, leading to poor soldering connections and potential functionality issues.

Understanding the underlying causes, potential implications, and viable solutions for managing tombstoning is essential for maintaining the integrity and reliability of printed circuit boards.

In this detailed exploration, we will delve into the root causes of tombstoning, analyze its potential impacts on PCBs, and provide effective strategies to prevent and address this prevalent soldering issue.

Causes of Tombstoning:

Tombstoning primarily results from imbalances in the soldering process, including asymmetric pad designs, uneven component placement, or inconsistent temperature distribution during reflow soldering.

Factors such as varying pad sizes, discrepancies in solder paste application, and differences in the component’s thermal characteristics can contribute to the unequal wetting of the solder, leading to the vertical displacement of the component during the reflow process and the subsequent formation of tombstone-shaped solder joints.

Implications of Tombstoning on PCBs:

Tombstoning can have significant implications on the functionality and reliability of PCBs, particularly in intricate electronic circuits and systems.

The occurrence of tombstoning can result in incomplete solder joints, leading to poor electrical connections, increased resistance, and potential signal integrity issues.

Additionally, tombstoning can compromise the mechanical stability of the soldered component, potentially leading to mechanical failures, reduced shock and vibration resistance, and decreased overall performance of the PCB assembly.

Identifying Tombstoning:

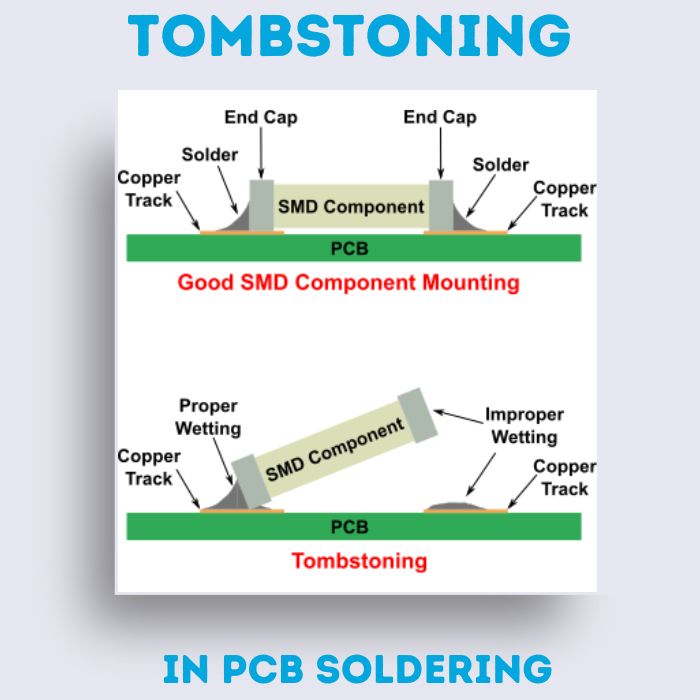

Identifying tombstoning requires a meticulous visual inspection of the soldered components, focusing on the vertical orientation of surface mount devices relative to their neighbouring components or solder pads on the PCB. Tombstoned components typically appear as raised, vertically oriented structures, with one end lifted off the PCB surface, resembling the shape of a tombstone.

Utilizing magnification tools, such as magnifying lenses or digital microscopes, can aid in the accurate identification and assessment of tombstoning during the inspection process.

Remedies and Prevention Strategies:

To effectively manage tombstoning and prevent its occurrence, implementing targeted remedies and preventive strategies is crucial during the PCB assembly process. Ensuring balanced pad designs and symmetric component placement, particularly for components with different thermal characteristics, can promote uniform solder wetting and mitigate the risk of tombstoning.

Additionally, optimizing the reflow temperature profile to achieve uniform heating across the PCB assembly and employing appropriate reflow soldering techniques, such as optimized reflow profiles and controlled cooling rates, can aid in reducing the likelihood of tombstoning.

Implementing advanced soldering technologies, such as vapour phase or selective soldering, can provide more precise control over the soldering process and minimize the risk of tombstoning, particularly for complex PCB assemblies or components with high thermal mass.

Conducting comprehensive design reviews and simulations to assess the thermal characteristics and soldering profiles of critical components can further enhance the prevention and management of tombstoning, ensuring the production of robust, high-quality PCB assemblies and electronic products.

Conclusion:

In conclusion, comprehensively understanding the complexities of tombstoning in PCB soldering is pivotal for upholding the reliability and performance of electronic devices and systems. By addressing the root causes, assessing the implications, and adopting effective remedies and prevention strategies, manufacturers and electronics enthusiasts can significantly enhance the soldering quality and integrity of their PCB assemblies, contributing to the development of robust, high-functioning electronic applications and technologies.