Solder bridges are a common occurrence in PCB soldering, characterized by the unintentional formation of excess solder connecting two adjacent pads or leads, often resulting in short circuits and compromised electrical connections.

Understanding the root causes, implications, and viable solutions for eliminating solder bridges is essential for maintaining the integrity and reliability of printed circuit boards.

In this detailed exploration, we will dissect the causes of solder bridges, analyze their effects on PCBs, and provide effective strategies to prevent and address this prevalent soldering issue.

Causes of Solder Bridges:

Solder bridges primarily stem from the excessive application of solder, often due to imprecise soldering techniques, the use of inappropriate soldering equipment, or insufficient understanding of the soldering process.

Factors such as excessive solder paste application, inadequate flux control, and improper soldering iron temperature regulation can contribute to the formation of solder bridges, leading to unintended electrical connections between neighboring components or conductive elements on the PCB.

Impacts of Solder Bridges on PCBs:

The presence of solder bridges can have detrimental effects on the functionality and reliability of PCBs, particularly in intricate electronic circuits and systems.

Solder bridges can result in short circuits, causing disruptions in the flow of current and potentially damaging sensitive electronic components.

This can lead to catastrophic consequences, including overheating, component failure, or even irreversible damage to the entire PCB assembly, ultimately compromising the overall performance and longevity of electronic devices.

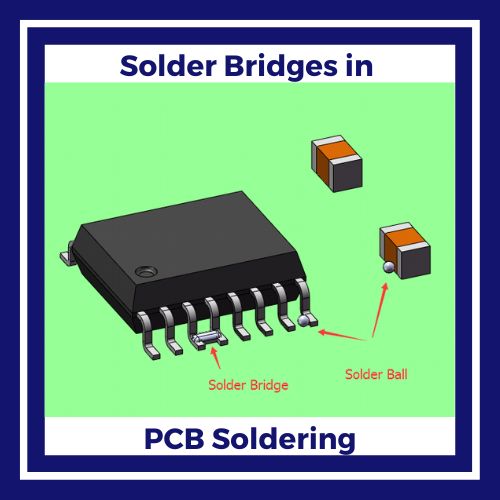

Identifying Solder Bridges:

Identifying solder bridges necessitates a comprehensive visual inspection of the soldered joints, particularly between closely spaced components or adjacent solder pads on the PCB.

Solder bridges typically appear as irregular or unintended connections of solder between two or more conductive elements, often forming shiny, continuous pathways that deviate from the intended soldering pattern.

Utilizing magnification tools, such as magnifying glasses or microscopes, can aid in the accurate identification and assessment of solder bridges during the inspection process.

Remedies and Prevention Strategies:

To effectively eliminate solder bridges and prevent their occurrence, implementing targeted remedies and preventive strategies is crucial during the soldering process.

Employing controlled solder paste deposition techniques, such as stencil printing or precise solder paste dispensing, can help minimize the risk of excess solder accumulation and subsequent solder bridging.

Furthermore, incorporating the appropriate flux type and quantity, as recommended by the solder and component manufacturers, can facilitate optimal solder wetting and mitigate the formation of unintended solder connections.

Adhering to proper soldering temperature profiles, maintaining consistent soldering iron tip sizes, and utilizing soldering irons with fine tips or specialized nozzles can aid in achieving precise solder deposition and minimizing the likelihood of solder bridges. Implementing automated optical inspection (AOI) systems or advanced soldering equipment with built-in quality control mechanisms can further enhance the detection and prevention of solder bridges, ensuring the production of high-quality, defect-free PCB assemblies and electronic products.

Conclusion:

In conclusion, comprehensively understanding the complexities of solder bridges in PCB soldering is pivotal for upholding the reliability and performance of electronic devices and systems.

By addressing the root causes, assessing the impacts, and adopting effective remedies and prevention strategies, manufacturers and electronics enthusiasts can significantly enhance the soldering quality and integrity of their PCB assemblies, contributing to the development of robust, high-functioning electronic applications and technologies.